Page 5 - VESBO OPACA PLUS Brochure

P. 5

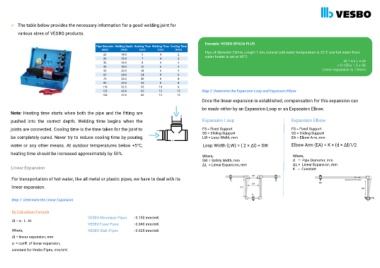

The table below provides the necessary information for a good welding joint for

various sizes of VESBO products.

Example: VESBO OPACA PLUS

Pipe Diameter Welding Depth Heating Time Welding Time Cooling Time

(mm) (mm) (sec) (sec) (min)

20 14.0 5 4 2 Pipe of diameter 25mm, Length 1.5m, normal cold water temperature is 25°C and hot water from

25 15.0 7 4 2 water heater is set at 60°C.

32 16.5 8 6 4 Δl = α x L x Δt

40 18.0 12 6 4 = 0.150 x 1.5 x 35

50 20.0 18 6 4 Linear expansion is 7.8mm

63 24.0 24 8 6

75 26.0 30 8 8

90 29.0 40 8 8

110 32.5 50 10 8

125 46.0 65 12 12 Step 2: Determine the Expansion Loop and Expansion Elbow

160 47.0 80 15 15

Once the linear expansion is established, compensation for this expansion can

be made either by an Expansion Loop or an Expansion Elbow.

Note: Heating time starts when both the pipe and the fitting are

pushed into the correct depth. Welding time begins when the Expansion Loop Expansion Elbow

joints are connected. Cooling time is the time taken for the joint to FS = Fixed Support FS = Fixed Support

SS = Sliding Support SS = Sliding Support

be completely cured. Never try to reduce cooling time by pouring LW = Loop Width, mm EA = Elbow Arm, mm

water or any other means. At outdoor temperatures below +5°C, Loop Width (LW) = ( 2 × Δl) + SW Elbow Arm (EA) = K × (d × Δl)1/2

heating time should be increased approximately by 50%.

Where, Where,

SW = Safety Width, mm d = Pipe Diameter, mm

ΔL = Linear Expansion, mm ΔL = Linear Expansion, mm

Linear Expansion K = Constant

For transportation of hot water, like all metal or plastic pipes, we have to deal with its

linear expansion.

Step 1: Determine the Linear Expansion

By Calculation Formula

VESBO Monolayer Pipes : 0.150 mm/mK

Δl = α . L. Δt

VESBO Faser Pipes : 0.040 mm/mK

Where, VESBO Stabi Pipes : 0.025 mm/mK

Δl = linear expansion, mm

α = coeff. of linear expansion,

constant for Vesbo Pipes, mm/mK