Page 3 - VESBO OXYPEX Brochure

P. 3

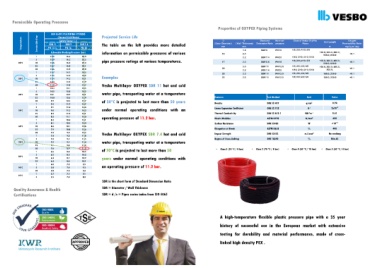

Permissible Operating Pressures

Properties of OXYPEX Piping Systems

DIN 16893 PEX PIPING SYSTEMS Projected Service Life

(Hot and Cold Water)

Temperature Service Life Year PN 12.5 Safety Factor 1.5 SDR 7.4 The table on the left provides more detailed (Outer Diameter) ( Wall Thickness) Dimension Ratio Nominal Class of Vesbo OxyPex Coil Length Permeability Ratio

D S Standard

Oxygen

Pipes

pressure

SDR 11

SDR 9

m

mg.O 2 /m².day

mm

mm

PN 16

PN 20

Allowable Working Pressure (bar) information on permissible pressures of various 16 1.8 SDR 9 PN 16 1/8; 2/8; 4/10; 5/8 160.0, 200.0, 400.0, <0.1

2.0

1 13.2 16.6 20.9 2.2 SDR 7.4 PN 20 1/10; 2/10; 4/10; 5/10 500.0, 600.0

5 12.9 16.3 20.5 pipe pressure ratings at various temperatures. 1/8; 2/8; 4/10; 5/8 160.0, 200.0, 400.0,

20°C 10 12.8 16.2 20.4 17 2.0 SDR 8.5 PN 16 500.0, 600.0 <0.1

25 12.7 16.0 20.1 2.0 SDR 11 PN 12.5 1/6; 2/6; 4/8; 5/6 160.0, 200.0, 400.0,

50 12.6 15.9 20.0 20 2.8 SDR 7.4 PN 20 1/10; 2/10; 4/10; 5/10 500.0, <0.1

1 11.7 14.7 18.5 25 2.3 SDR 11 PN 12.5 1/6; 2/6; 4/8; 5/6 160.0, 200.0 <0.1

5 11.5 14.4 18.2 Examples 1/6; 2/6; 4/8; 5/6

30°C 10 11.4 14.3 18.1 32 2.9 SDR 11 PN 12.5 160.0, 200.0 <0.1

25 11.3 14.2 17.9

50 11.2 14.0 17.7 Vesbo Multilayer OXYPEX SDR 11 hot and cold

1 10.4 13.1 16.5

5 10.2 12.8 16.2

40°C 10 10.1 12.7 16.1 water pipe, transporting water at a temperature

25 10.0 12.6 15.9 Features Test Method Unit Value

50 9.9 12.5 15.7 of 30°C is projected to last more than 50 years

1 9.3 11.7 14.7 Density DIN 53 497 g/cm 3 0.94

5 9.1 11.4 14.4 Linear Expansion Coefficient DIN 53 752 K -1 2x10 -4

50°C 10 9.0 11.3 14.3 under normal operating conditions with an

25 8.9 11.2 14.1 Thermal Conductivity DIN 52 612-1 WK -1 m -1 0.41

50 8.8 11.1 14.0 operating pressure of 11.2 bar.

1 8.3 10.4 13.1 Elastic Modulus ASTM D790 N/mm 2 600

5 8.1 10.2 12.9 Surface Resistance DIN 53482 W >10 12

60°C 10 8.0 10.1 12.8

25 7.9 10.0 12.6 Elongation at Break ASTM D638 % 400

50 7.9 9.9 12.5 Vesbo Multilayer OXYPEX SDR 7.4 hot and cold Impact Strength DIN 53453 m.J.mm 2 No cracking

1 7.4 9.3 11.8

5 7.3 9.1 11.5 Degree of Cross-Linking DIN 16892 % Min.65

70°C 10 7.2 9.1 11.4 water pipe, transporting water at a temperature

25 7.1 9.0 11.3

50 7.0 8.9 11.2 of 70°C is projected to last more than 50 • Class 1 (70 °C / 8 bar) • Class 2 (70 °C / 8 bar) • Class 4 (60 °C / 10 bar) • Class 5 (60 °C / 8 bar)

1 6.6 8.4 10.5

5 6.5 8.2 10.3

80°C

10 6.4 8.1 10.2 years under normal operating conditions with

25 6.4 8.0 10.1

1 6.0 7.5 9.5

90°C 5 5.8 7.4 9.3 an operating pressure of 11.2 bar.

10 5.8 7.3 9.2

1 5.7 7.1 9.1

95°C

5 5.5 7.0 8.8

SDR is the short form of Standard Dimension Ratio

Quality Assurance & Health SDR = Diameter / Wall Thickness

Certifications SDR = d /s = Pipes series index from ISO 4065

A high-temperature flexible plastic pressure pipe with a 35 year

history of successful use in the European market with extensive

testing for durability and material performance, made of cross-

linked high density PEX .