Page 3 - VESBO PERT Brochure

P. 3

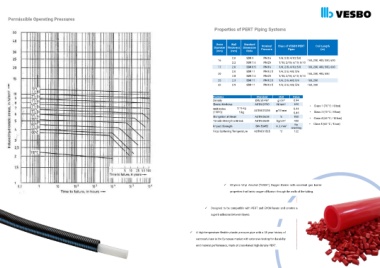

Permissible Operating Pressures

Properties of PERT Piping Systems

Outer Wall Standard

Nominal

Diameter Thickness Dimension Pressure Class of VESBO PERT Coil Length

(m)

Pipes

(mm) (mm) Ratio

2.0 SDR 9 PN 16 1/8; 2/8; 4/10; 5/8

16 160, 200, 400, 500, 600

2.2 SDR 7.4 PN 20 1/10; 2/10; 4/10; 5/10

17 2.0 SDR 8.5 PN 16 1/8; 2/8; 4/10; 5/8 160, 200, 400, 500, 600

2.0 SDR 11 PN 12.5 1/6; 2/6; 4/8; 5/6

20 160, 200, 400, 500

2.8 SDR 7.4 PN 20 1/10; 2/10; 4/10; 5/10

25 2.3 SDR 11 PN 12.5 1/6; 2/6; 4/8; 5/6 160, 200

32 2.9 SDR 11 PN 12.5 1/6; 2/6; 4/8; 5/6 160, 200

Features Standard Unit Value

Density DIN 53 497 g/cm 3 0.94

Elastic Modulus ASTM D790 N/mm 2 620 • Class 1 (70 °C / 8 bar)

Melt Index 2.16 kg ASTM D1238 g/10 min 0.14

(190°C) 5 kg 0.45 • Class 2 (70 °C / 8 bar)

Elongation at Break ASTM D638 % 850

• Class 4 (60 °C / 10 bar)

Tensile Strength at Break ASTM D638 kg/cm 2 430

No • Class 5 (60 °C / 8 bar)

Impact Strength DIN 53453 m.J.mm 2

cracking

Vicat Softening Temperature ASTM D1525 °C 122

Ethylene Vinyl Alcohol (‘’EVOH’’) Oxygen Barrier with excellent gas barrier

properties that limits oxygen diffusion through the walls of the tubing.

Designed to be compatible with PERT and EVOH layers and creates a

superb adhesion between layers

A high-temperature flexible plastic pressure pipe with a 35 year history of

successful use in the European market with extensive testing for durability

and material performance, made of cross-linked high density PERT.