Page 3 - VESBO U-PVC Brochure

P. 3

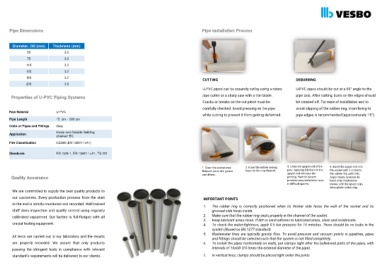

Pipe Dimensions Pipe Installation Process

Diameter, OD (mm) Thickness (mm)

50 3.0

75 3.0

110 3.2

125 3.2

160 3.2

CUTTING DEBURRING

200 3.9

U-PVC pipes can be squarely cut by using a rotary U-PVC pipes should be cut at a 90° angle to the

Properties of U-PVC Piping Systems pipe cutter or a sharp saw with a thin blade. pipe axis. After cutting, burrs on the edges should

Cracks or breaks on the cut piece must be be cleaned off. For ease of installation and to

carefully checked. Avoid pressing on the pipe avoid slipping of the rubber ring, chamfering to

Raw Material U-PVC

while cutting to prevent it from getting deformed. pipe edges is recommended (approximately 15°).

Pipe Length 15 cm - 600 cm

Color of Pipes and Fittings Grey

Inside and Outside Building

Application

(marked ’B’)

Fire Classification CS3d0 (EN 13501-1+A1)

Standards EN 1329-1, EN 13501-1+A1, TS 201

1. Clean the socket area. 2. Insert the rubber sealing 3. Clean the spigot end of the 4. Insert the spigot end into

Remove sand, dirt, grease ring into the ring channel. pipe. Applying lubricant to the the socket until it contacts

and debris. spigot end will ease the the rubber ring uniformly.

Quality Assurance jointing. Push-fit system Apply steady pressure by

provides easy installation even hand or by mechanical

in difficult spaces. means until the spigot slips

through the rubber ring.

We are committed to supply the best quality products to

our customers. Every production process from the start IMPORTANT POINTS

to the end is strictly monitored and recorded. Well-trained

1. The rubber ring is correctly positioned when its thicker side faces the wall of the socket and its

staff does inspection and quality control using regularly grooved side faces inside.

calibrated equipment. Our factory is full-fledged with all 2. Make sure that the rubber ring seats properly in the channel of the socket.

3. Keep lubricant areas clean. If dirt or sand adheres to lubricated areas, clean and re-lubricate.

crucial testing equipment. 4. To check the water-tightness, apply 0.5 bar pressure for 15 minutes. There should be no leaks in the

system (Based on EN 1277 standard).

5. Wastewater lines are typically gravity flow. To avoid pressure and vacuum points in pipelines, pipes

All tests are carried out in our laboratory and the results

and fittings should be selected such that the system is not filled completely.

are properly recorded. We assure that only products 6. To install the pipes horizontally on walls, put clamps right after the belled-end parts of the pipes, with

passing the stringent tests in compliance with relevant intervals of 10xOD (10 times the external diameter of the pipe).

standard’s requirements will be delivered to our clients. 7. In vertical lines, clamps should be placed right under the joints