Page 1 - VESBO PPR PRODUCT DATA SHEET

P. 1

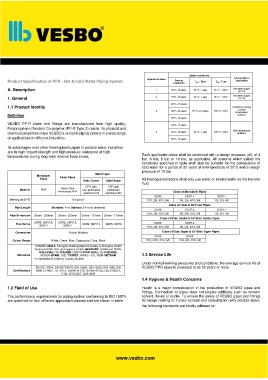

System conditions

Typical field of

Application class

Product Specification of PPR - Hot & Cold Water Piping System Service T max - Time T mal - Time application

conditions

A. Description 1 60°C- 49 years 80 °C- 1 year 95 °C - 100 h Hot water supply

(60 °C)

Hot water supply

1. General 2 70°C- 49 years 80 °C- 1 year 95 °C - 100 h (70 °C)

20°C- 2.5 years

1.1 Product Identity Underfloor heating

4 40°C- 20 years 70 °C- 2.5 years 100 °C- 100 h and low

temperature

Definition radiators

60°C- 25 years

VESBO PP-R pipes and fittings are manufactured from high quality, 20°C- 14 years

Polypropylene Random Co-polymer (PP-R Type 3) resins. Its physical and High temperature

chemical properties make VESBO a versatile piping system in a wide range 5 60°C- 25 years 90 °C- 1 year 100 °C- 100 h radiators

of applications in different industries. 80°C- 10 years

Its advantages over other thermoplastic pipes in potable water industries

are its high impact strength and high pressure resistance at high

temperatures during long-term internal hoop stress. Each application class shall be combined with a design pressure, pD, of 4

bar, 6 bar, 8 bar or 10 bar, as applicable. All systems which satisfy the

conditions specified in table shall also be suitable for the conveyance of

cold water for a period of 50 years at a temperature of 20°C and a design

pressure of 10 bar.

Stabi Pipes

Monolayer

Pipes Faser Pipes All heating installations shall only use water or treated water as the transfer

Stabi Centro Stabi Super fluid.

PPR with PPR with

Glass Fiber

Material PPR non-perforated perforated

Reinforced PPR Class of Monolayer Pipes

aluminum foil aluminum foil

SDR6 SDR7.4 SDR11

Density at 23 °C 0.9 gr/cm³ 1/10, 2/8, 4/10, 5/6 1/8, 2/6, 4/10, 5/6 1/6, 2/4, 4/6

Class of Faser & UV Faser Pipes

Pipe Length Standard: 4 m; Optional:3-6 m on demands

SDR6 SDR7.4 SDR11

1/10, 2/8, 4/10, 5/6 1/8, 2/6, 4/10, 5/6 1/6, 2/4, 4/6

Pipe Dimension 20mm - 250mm 20mm - 250mm 20mm - 110mm 20mm - 110mm

Class of Stabi Centro & UV Stabi Centro Pipes

SDR6, SDR7.4, SDR6, SDR7.4, SDR6 SDR7.4

Pipe Series SDR6, SDR7.4 SDR5, SDR6

SDR11 SDR11 1/10, 2/8, 4/10, 5/6 1/8, 2/6, 4/10, 5/6

Connection Fusion Welding Class of Stabi Super & UV Stabi Super Pipes

SDR5 SDR6

Colour Range White, Green, Blue, Cappuccino, Grey, Black 1/10, 2/10, 4/10, 5/8 1/10, 2/8, 4/10, 5/6

CESMEC-CHILE, Shanghai Building Material Quality & Shanghai Health

Bureau-CHINA, SKZ and Hygiene Institut-GERMANY, SIRIM and SPAN-

MALAYSIA, ITB-POLAND, CERTIF-PORTUGAL, SGR-RUSSIA,

Standards AENOR-SPAIN, TSE- TURKEY, WRAS – UK, VIBM-VIETNAM 1.3 Service Life

* In Alphabetical Order by Country Names

Under normal working pressures and conditions, the average service life of

EN ISO 15874, DIN 8077/8078, DIN 16962, DIN 16928, DIN 1988, DIN VESBO PPR pipes is projected to be 50 years or more.

Certifications 2999,TS 9937, TS 13715, DVGW W 270, DVGW W 542, ISO 21003-2,

KTW, DVS 2207, DVS 2208

1.4 Hygiene & Health Concerns

1.2 Field of Use Health is a major consideration in the production of VESBO pipes and

fittings. Connection of pipes does not require additives such as cement

The performance requirements for piping system conforming to ISO 15874 solvent, fluxes or solder. To ensure the safety of VESBO pipes and fittings

are specified for four different application classes and are shown in table. for usage relating to human contact and consumption with potable water,

the following standards are strictly adhered to:

www.vesbo.com