Page 28 - INCOLA EXCLUSIVE DATA CATALOGUE

P. 28

Fire Safety

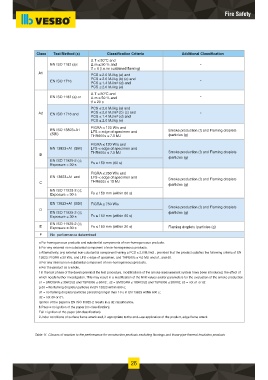

Class Test Method (s) Classification Criteria Additional Classification

Δ T ≤ 30°C and

EN ISO 1182 (a): Δ m ≤ 50 % and -

tf = 0 (i.e.no sustained flaming)

A1

PCS ≤ 2.0 MJ/kg (a) and

PCS ≤ 2.0 MJ/kg (b) (c) and

EN ISO 1716 -

PCS ≤ 1.4 MJ/m² (d) and

PCS ≤ 2.0 MJ/kg (e)

Δ T ≤ 50°C and

EN ISO 1182 (a) or Δ m ≤ 50 % and -

tf ≤ 20 s

PCS ≤ 2.0 MJ/kg (a) and

A2 EN ISO 1716 and PCS ≤ 2.0 MJ/m² (b) (c) and -

PCS ≤ 1.4 MJ/m² (d) and

PCS ≤ 2.0 MJ/kg (e)

FIGRA < 120 W/s and

EN ISO 13823+A1 Smoke production (f) and Flaming droplets

LFS < edge of specimen and

(SBI) /particles (g)

THR600s ≤ 7.5 MJ

FIGRA ≤ 120 W/s and

EN 13823+A1 (SBI) LFS < edge of specimen and

THR600s ≤ 7.5 MJ Smoke production (f) and Flaming droplets

B

/particles (g)

A1 EN ISO 11925-2 (ı);

(Sand, gravel, gypsum, concrete, brick, ceramic, glass Exposure = 30 s Fs ≤ 150 mm (60 s)

wool, rock wool, perlite)

FIGRA ≤ 250 W/s and

A2

( Glass wool and stone wool with organic binding) EN 13823+A1 and LFS < edge of specimen and Smoke production (f) and Flaming droplets

THR600s ≤ 15 MJ

C

/particles (g)

EN ISO 11925-2 (ı);

Fs ≤ 150 mm (within 60 s)

Exposure = 30 s

EN 13823+A1 (SBI) FIGRA ≤ 750 W/s

Smoke production (f) and Flaming droplets

D

EN ISO 11925-2 (ı); /particles (g)

B1 Exposure = 30 s Fs ≤ 150 mm (within 60 s)

(Gypsum-cardboard plate, cement wood

EN ISO 11925-2 (ı);

shavings, polystyrene and polyurethane E Exposure = 30 s Fs ≤ 150 mm (within 20 s) Flaming droplets /particles (g)

foam-sandwich panel with fire retardant additive)

F No performance determined

a For homogeneous products and substantial components of non-homogeneous products.

b For any external non-substantial component of non-homogeneous products.

c Alternatively, any external non-substantial component having a PCS ≤ 2,0 MJ/m2 , provided that the product satisfies the following criteria of EN

13823: FIGRA ≤ 20 W/s, and LFS < edge of specimen, and THR600s ≤ 4,0 MJ, and s1, and d0.

d For any internal non-substantial component of non-homogeneous products.

e For the product as a whole.

f In the last phase of the development of the test procedure, modifications of the smoke measurement system have been introduced, the effect of

which needs further investigation. This may result in a modification of the limit values and/or parameters for the evaluation of the smoke production.

s1 = SMOGRA ≤ 30m2/s2 and TSP600s ≤ 50m2 ; s2 = SMOGRA ≤ 180m2/s2 and TSP600s ≤ 200m2; s3 = not s1 or s2

g d0 = No flaming droplets/ particles in EN 13823 within 600 s;

d1 = no flaming droplets/ particles persisting longer than 10 s in EN 13823 within 600 s;

B2 d2 = not d0 or d1.

(Wood silicone joint filler, polystyrene Ignition of the paper in EN ISO 11925-2 results in a d2 classification.

and polyurethane foam) h Pass = no ignition of the paper (no classification);

Fail = ignition of the paper (d2 classification).

i Under conditions of surface flame attack and, if appropriate to the end–use application of the product, edge flame attack

B3

( Wood shavings, paper esc.) Table 11. Classes of reaction to fire performance for construction products excluding floorings and linear pipe thermal insulation products

26